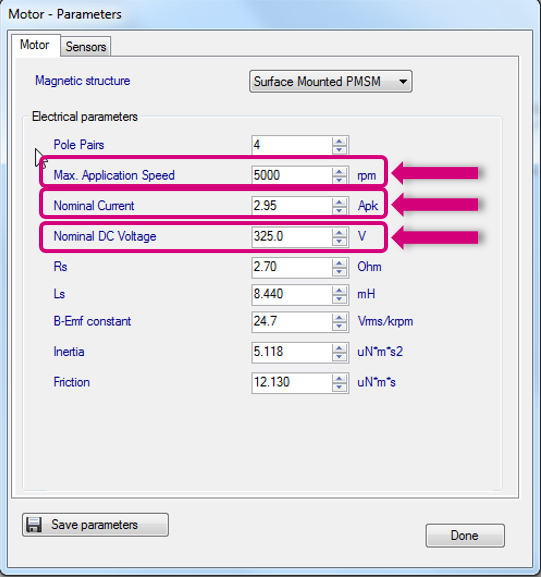

1. Max Rated Speed, Nominal Current and Nominal DC Voltage parameters

- Set the Max Rated Speed to the maximum motor speed according to the application specifications.

- Set the Nominal Current to the maximum peak current provided to each of the motor phases according to the motor specifications.

- Set the Nominal DC Voltage to the value of the DC bus provided to the inverter or the rectified value of AC input.

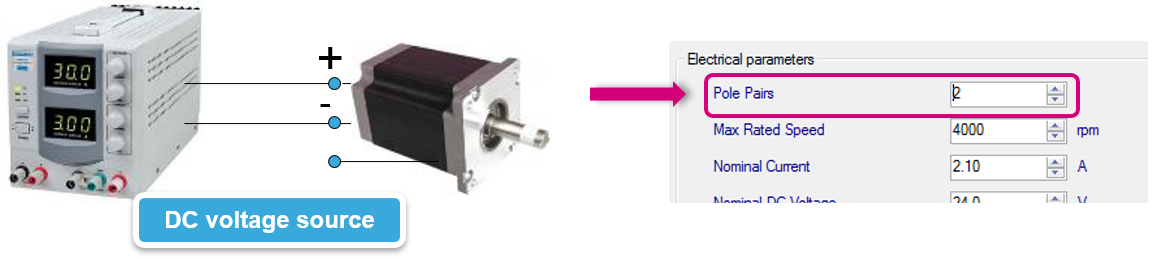

2. Pole pair (number) parameter

- The number of pole pairs is usually provided by the motor supplier, but in case it’s not or if you’d like to double-check it:

- Connect a DC power supply between two (of the three) motor phases and provide up to 5% of the expected nominal DC bus voltage. (You may also set the current protection to the nominal motor current.)

- Rotate the motor with your hands, you should notice a little resistance, otherwise:

- If you are not able to rotate the motor, decrease the applied voltage.

- If the motor does not generate any resistance, gradually increase the applied voltage.

- The number of rotor stable positions in one mechanical turn represents the number of pole pairs.

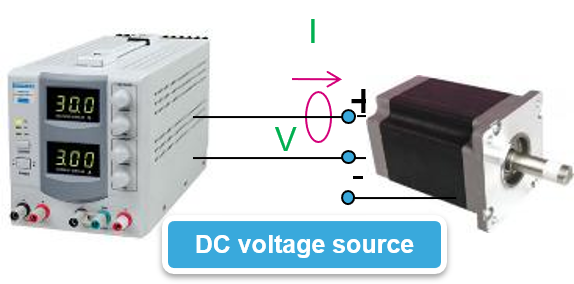

3. Stator resistance and inductance parameters

- Using the multimeter, measure the DC stator resistance phase-to-phase (Rs) and divide it by two.

- Connect the DC voltage between two motor phases.

- Connect the oscilloscope voltage and current probes as shown in the figure.

- Increase the voltage up to the value where the current equals the nominal value, so the rotor aligns with the generated flux.

- Don’t move the rotor anymore.

- Disable the current protection of the DC voltage source.

- Unplug one terminal of the voltage source cable without switching it off.

- Plug the voltage source rapidly and monitor on the scope the voltage and current waveform until you get something like the one shown in the figure.

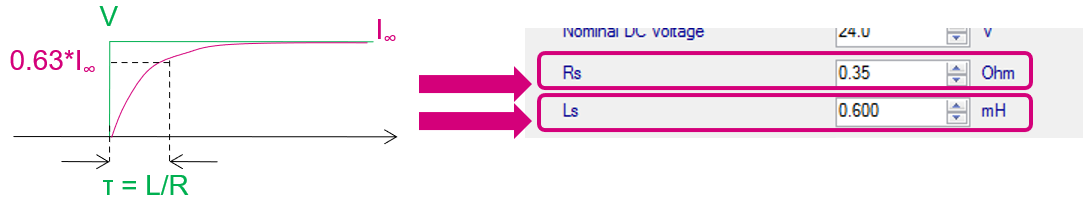

- The measurement is good if the voltage can be assimilated to a step and the current increase such as I∞ * (1-e- t *L/R).

- Measure the time required for the current waveform to rise to 63%.

- This time is Ld/Rs constant. Multiply it by Rs and you’ll get the Ld value.

4. Back EMF constant Ke

- The Back-EMF constant represents the proportionality constant between the mechanical motor speed and the amplitude of the B-EMF induced into the motor phases:

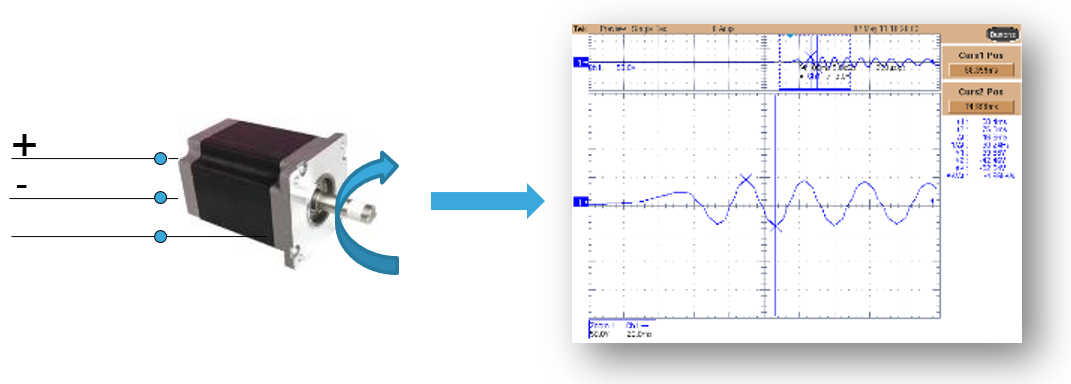

- To measure Ke, it usually suffices to turn the motor with your hands (or using a drill or another motor mechanically coupled) and use an oscilloscope to look for the phase-to-phase induced voltage (VBemf )

- Measure the VBemf frequency (fBemf) and the peak-to-peak amplitude (VBemf –A)

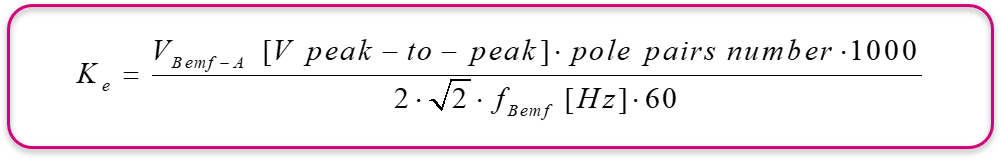

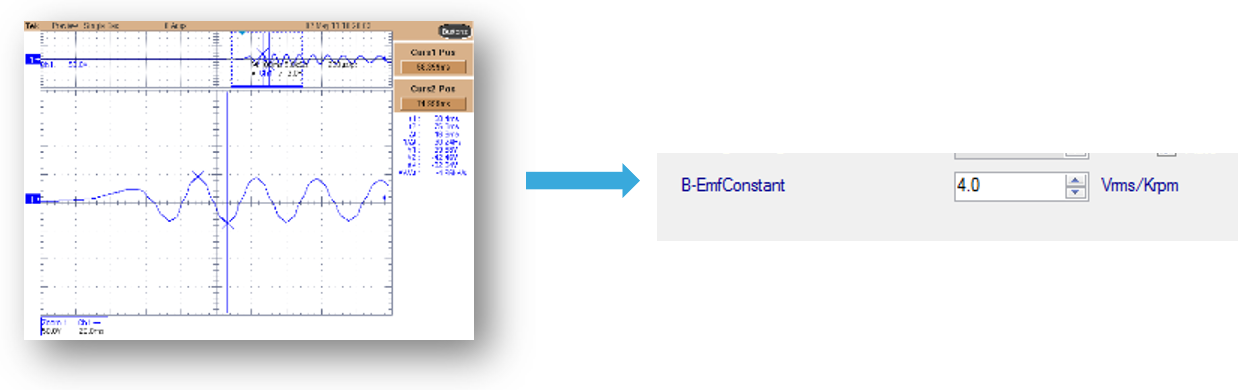

- Compute Ke in VRMS / KRPM: